Many medical treatments, including vaccines, insulin, antivenom drugs and antibodies are made up of proteins – amino acid chains folded into a specific shape. These substances have to be preserved before they reach the patient by refrigeration at 2-8°C, otherwise they spoil, which leads to the denaturation of the whole vaccine. Majority of the time, this is not a chemical reaction but a physical unfolding of the amino acid chains. Maintaining this cold chain is a serious burden in healthcare and in many countries around the world cold chain cannot be maintained due to the lack of energy and infrastructure.

More than 7 million people worldwide die from vaccine-preventable diseases every year. Among those, more that 2.5 million are children under 5. Failures of the cold chain lead to ineffective vaccines, and children are left exposed to life-threatening diseases. The minimum cost of maintaining the cold chain is estimated at US$300 million annually, but it is higher in reality as this does not include electricity, infrastructure and wastes. Any scientific advance which can end this dependence will have a transformative impact in saving lives.

UNICEF recorded an approximately 80% wastage of vaccines due to problems with cold chain in the 1990s. Today, although the problem has been greatly reduced, it is estimated that there is still 40% wastage of vaccines when transported to developing countries. Indeed, the only two diseases to have been entirely eliminated by vaccination, smallpox (humans) and rinderpest (cattle), had naturally heat-stable vaccines. Similarly antibiotic and antivenom drugs, whose use may be unpredictable, are very hard to transport or store in many hot countries around the globe.

I am a materials chemist, working on silica-based materials for more than 15 years now. I have two daughters, who were born in the UK. When I took them to be vaccinated I observed how the doctor removed the vaccines from the fridge and administered them directly. That’s when I got curious about the thermal stability of vaccines. It occurred to me that silica might be applied to vaccines to make them thermally stable at room temperature. I searched the literature and to my surprise it appeared that this approach had not been explored before.

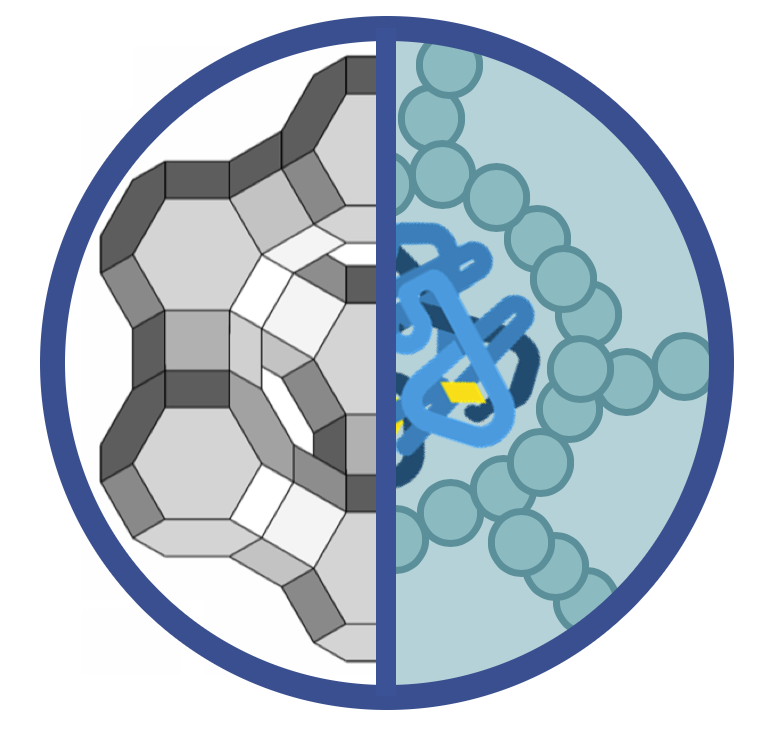

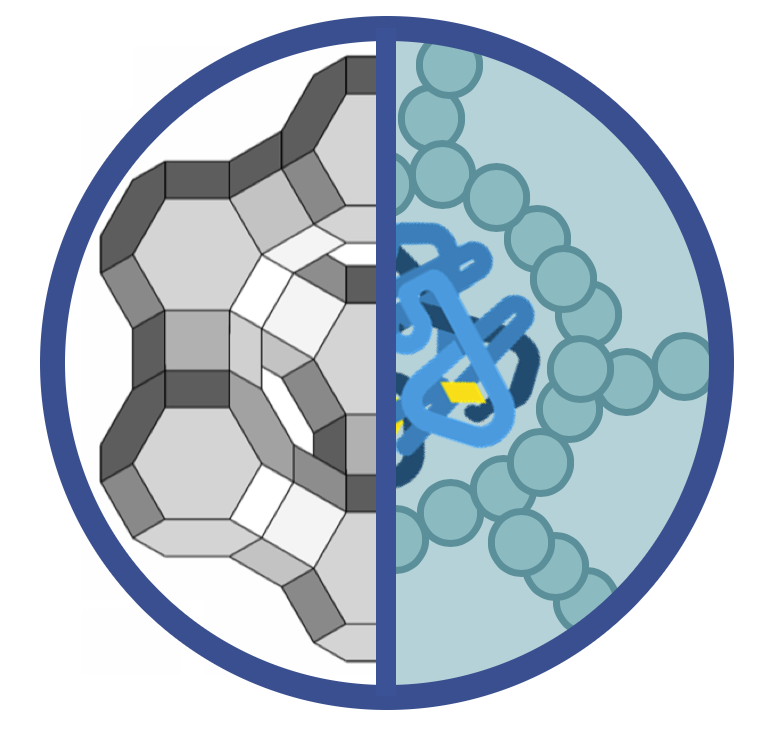

Our novel method for vaccine preservation is based on applying a small amount of silica to grow a tailored coat around each vaccine protein. Once this is done, they can be stored or transported at room temperatures. When vaccines are needed for administration, protective coat can be broken and vaccines can be administered to the patients. Our in vitro and in vivo (mice) studies show that both protein structure and function are preserved by silica, even at really harsh, denaturing conditions.We are also working on applying similar methods to other important biopharmaceuticals, such as antibodies, insulin and enzymes.

Our first scientific manuscript describing this method has been published. The protocol is IP protected; the patent has been filed in August 2016.

We are interested making contact with manufacturers of vaccines and other biopharmaceuticals to explore practical applications and further development of the method.