Biodiesel

When Rudolph Diesel first demonstrated his combustion engine over a century ago it was fuelled by peanut oil and Diesel himself envisaged biodiesel as the fuel of the future. However, the cheap and plentiful crude oil of the twentieth century meant that interest in biodiesel has only recently been rekindled. For example, the EU has set targets to increase the proportion of biofuels in energy consumption to 5.75% by 2010 and 20% by 2020.

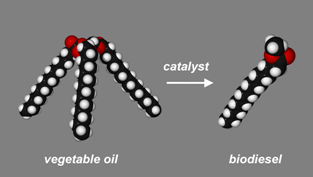

To make biodiesel, vegetable oil from

high-yielding oil crops such as rape is used. Vegetable oils are molecules called triglycerides,

which consist of three fatty

acid chains connected together by one glycerine unit. If used directly, the oil is too viscous and the glycerine clogs up

diesel engines, so each triglyceride molecule has to be broken down into three molecules of fatty acid methyl ester (FAME)

or biodiesel. This process is called transesterification and requires the use of a chemical catalyst (a species

that speeds up a chemical reaction but can be recovered intact afterwards). Current catalysts need very pure oil and they

make separation of biodiesel from by-products difficult. We are designing new molecular catalysts to overcome these

problems and make biodiesel production more efficient while also allowing impure feedstocks (such as chip fat) to be used.

To make biodiesel, vegetable oil from

high-yielding oil crops such as rape is used. Vegetable oils are molecules called triglycerides,

which consist of three fatty

acid chains connected together by one glycerine unit. If used directly, the oil is too viscous and the glycerine clogs up

diesel engines, so each triglyceride molecule has to be broken down into three molecules of fatty acid methyl ester (FAME)

or biodiesel. This process is called transesterification and requires the use of a chemical catalyst (a species

that speeds up a chemical reaction but can be recovered intact afterwards). Current catalysts need very pure oil and they

make separation of biodiesel from by-products difficult. We are designing new molecular catalysts to overcome these

problems and make biodiesel production more efficient while also allowing impure feedstocks (such as chip fat) to be used.

Although biodiesel can make a significant contribution to reducing dependence on fossil fuels, it is not the perfect solution. It is unlikely that sufficient raw materials will ever be available to meet demand without compromising the world's food supply, and agriculture itself is an energy-intensive industry. This means that we have to look to more radical solutions for the generation of energy in the longer term.

|

Design your own biodiesel catalyst by playing the CatChem game! (0.4 Mb) |

|

Watch the chemical reaction involved in making biodiesel!

Press the image to begin (2.9 Mb)

|

The Biodiesel Team

Prof. Matt Davidson, Dr Matthew Jones, Amanda Chmura, Chris Chuck.

More Information

- Download the biodiesel fact sheet (709 kb).

- Visit the Davidson Research Group web site.