| |

Medusa Waterbag |

|

Location |

Areas of Scarce Drinking Water |

Dates |

June 2000 - Present |

Client |

Medusa Water International |

Structural Engineer |

Buro Happold |

Project : |

|

|

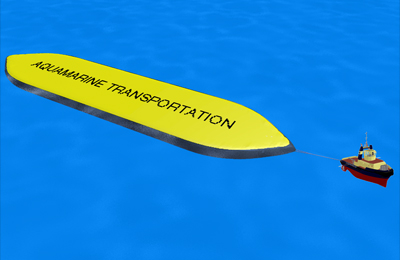

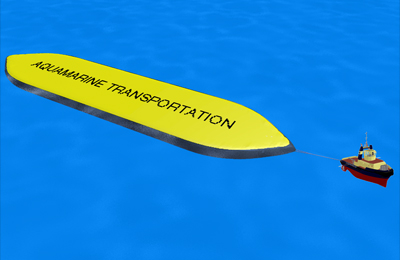

| Turn the concept of using extremely large fabric bags for the transportation

of fresh water into a commercial product. The aim is to design and build bags

the size of three football pitches to be more economical than desalination plants. |

My Role : |

|

|

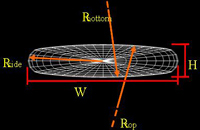

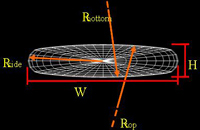

- Create software to parametrically generate geometry, properties and loading ready for analysis

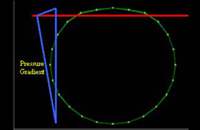

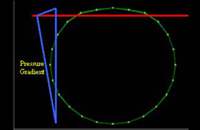

- Create software to tightly couple fluid density gradient pressure loading with structural dynamic relaxation solver

- Analysis of various towing scenarios

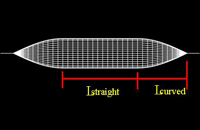

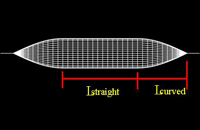

- Optimisation of bag shape between construction and in-service constraints

|