Some miscellaneous comments on adhesion

D. E. Packham,

Materials Research

Centre,

University of Bath.

For a collection of short, self-contained articles,

which together give comprehensive account

of the scientific, engineering and industrial aspects of adhesion, see:

D.E. Packham (ed.), Handbook of Adhesion, 2nd edition, Wiley, 2005.

available on line:

http://www3.interscience.wiley.com/cgi-bin/bookhome/111084161

However, some miscellaneous comments on adhesion are provided below

Bonds at the interface

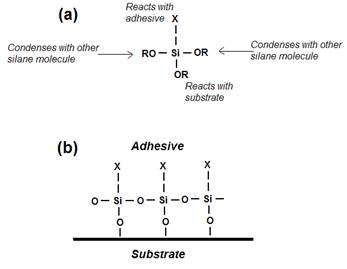

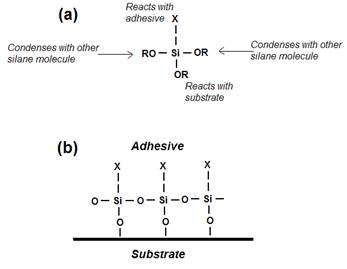

Organo-silane

adhesion promoters are widely used to enhance the adhesion and bond

durability with glass and metals. Typical structure (a) and postulated mode of

action (b) for a silane adhesion promoter. There is much evidence that their

mode of action is much more complex than this, e.g. see discussion in

D.E. Packham, Some contributions

of surface analysis to the development of adhesion theories, J. Adhesion 84,240–255(2008).

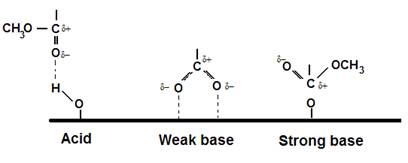

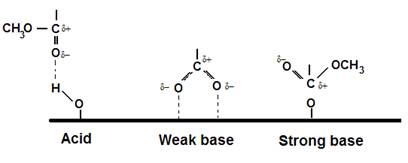

The next figure shows various interactions postulated

between PMMA and surfaces of differing

acidic and basic nature. It is based on work of

S.R. Leadley, and J.F. Watts, J. Adhesion 60(1-4) 175-196 (1997).

E.G. (Si) (Al)

(Ni)

H-bond (Si) ionic

(Al)* ion/dipole (Ni)

* indicating

hydrolysis of the ester and adsorption through the carboxylate anion

Rough surfaces

With rough

surfaces there may be serious problems of the adhesive's being abl to enter

proes and crevices on the substrate surface. This figure shows equilibrium penetration of a liquid into

cylindrical and "ink bottle" pores, after de Bruyne.

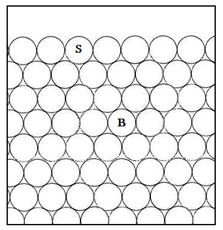

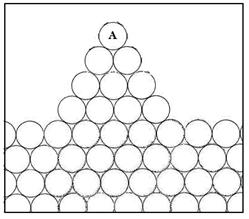

A rough surface will have a higher surface energy than a corresponding smooth one. This is

shown in the schematic diagram below. In this simplified two dimensional representation,

the bulk atom (B) has 6 nearest neighbours, the atom on a plane surface (S) has

4, and that on an asperity on a rough surface (A) only 2.

Some macroscopically rough

surfaces are known to enhance adhesion.

Here undercut TiW islands enhance adhesion of copper to silica. Based on

A.M.T. van der Putten, J. Electrochem.

Soc. 140, 2376(1993). (i) TiW

islands deposited (ii) Pd activator adsorbed and HF etching; (iii) electroless

Cu deposited; (iv) Cu electrodeposited.

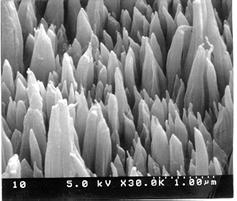

Some very rough surfaces can result from pretreatment prior

to adhesive bonding. Here are some microfibrous

surfaces (l to r): dendrites of zinc electrodeposited onto a zinc surface;

black CuO layer produced on copper; PTFE irradiated by argon ions. The last

based on S.K. Koh, S.C. Park, S.R. Kim, W.K. Choi, H.J. Jung, and K.D. Pae, J. Appl. Polym. Sci., 64,1913(1997), courtesy of the authors.

The increased

adhesion to microfibrous surfaces is often associated with increased

plastic deformation of the polymer during failure of the adhesive bond, e.g. substrate

surface after peeling LDPE from (a) polished copper and (b) copper with a microfibrous oxide surface:

The concentration of stress at the "fibre" tips

can be demonstrated using a photoelastic model [J.R.G. Evans, Ph.D. thesis,

University of Bath 1977]:

Polymer-polymer bonding

Bonds between

immiscible polymers (A & B) are usually very weak, but some interdiffusion

can occur if the interaction parameter is not too high, cf. R.P. Wool: Polymer interfaces: structure and strength,

Hanser, Munich (1995) & in Adhesion

Science and Engineering, Vol. II, Surfaces,

Chemistry and Applications, Assoc. Ed. Chaudhury, Manoj K. and Pocius, A.V.

Elsevier, p. 351-402, 2002

The figure shows how

the laminating temperature affects the adhesion of four different ethylene-octene

copolymers to polypropylene (ethylene-octene copolymers and polypropylene are

formally incompatible):

L. Godail and D.E.

Packham, J. Adhesion Sci. Technol. 15(11), 1305(2001).

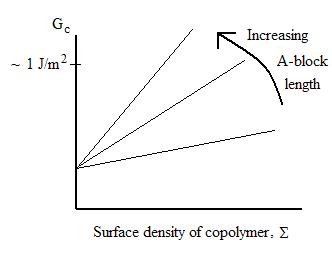

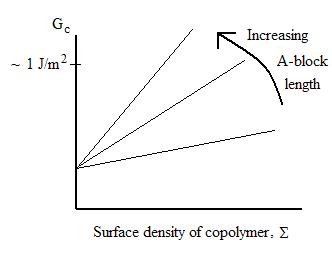

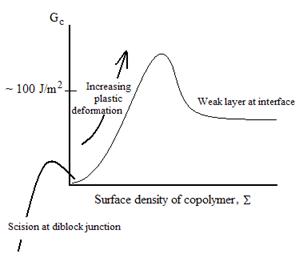

The interface between

immiscible polymers (A & B) may be strengthened by introduction of a diblock

copolymer AB. Here the A-block length is below entanglement length, so the

overall toughening is modest.

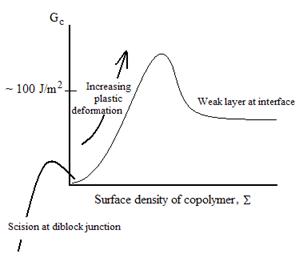

However, with a long chain length diblock copolymer, much

higher toughness is obtainable:

Results like these have been published by Creton and

colleagues, among others:

C. Creton, H.R. Brown, and V.R.

Deline, Macromolecules 27,

1774(1994).

C. Creton, H.R. Brown, and K.R.

Shull, Macromolecules 27, 3174(1994).

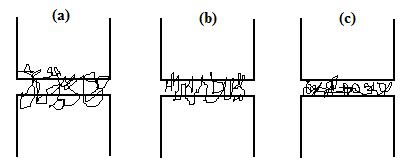

Random copolymers

– usually cheaper than diblocks – can also be used if the incompatibility

between the homopolymers is not too large. The molecule of a random copolymer

will form coils wandering many times across interface, forming many

"stiches". For large incompatibility the copolymer will simply form a

collapsed globules at interface, giving no enhancement of adhesion. Incompatibility

increases in the order (a), (b), (c):